The function of a clinical centrifuge structure depends entirely on its integrity. Manufacturers now use advanced dynamic balancing techniques to minimize vibration and increase lifespan. High-torque motors give smooth rotational power, and safeguards such as locking lids and imbalance sensors protect the user and sample from injury. In specialized lab arrangements, refrigerated clinical centrifuge maintain constant temperatures for biological samples. Miniaturized forms are also gaining ground, sacrificing space savings for speed and accuracy. These trends show the ongoing coming of age of clinical centrifuge engineering into versatility and reliability.

clinical centrifuge technology is a principal component in diverse manufacturing processes. In wastewater treatment, clinical centrifuge assist in separating sludge from liquids to improve recycling efficiency. In the manufacture of cosmetics, clinical centrifuge facilitate even emulsion and cream mixing. Crop research facilities apply it to analyze soil nutrients and plant extracts. It is also used in the manufacture of vaccines through the purification of viral particles and protein fractions. Through the ability to adapt to many substances and work requirements, clinical centrifuge continues to support industries seeking consistency, purity, and scalability.

{Keywords} in the future will evolve into fully networked instruments in smart laboratories. They will "communicate" with other analytical instruments through built-in digital platforms, making experimental workflows easier. Equipped with self-diagnostic systems, maintenance needs will be identified before any issues arise. Future clinical centrifuge models will emphasize energy efficiency and portability without compromising on speed or accuracy, while integration with robotics, AI-driven optimization, and user-friendly interfaces will redefine operations standards. In production and research environments, clinical centrifuge will play a key role in achieving higher productivity and sustainable performance.

For optimal performance, clinical centrifuge equipment needs to be handled cautiously and carefully. Operators need to ensure that rotors are balanced before use to avert vibration and wear. Regular cleaning of inner and outer surfaces prevents residues from building up that can impact results. Electric wiring should be inspected for loose or damaged cables. Storage of clinical centrifuge in a clean, temperature-controlled environment keeps its components. Regular professional maintenance and replacement of worn parts on schedule ensure smooth and efficient use of the device over time.

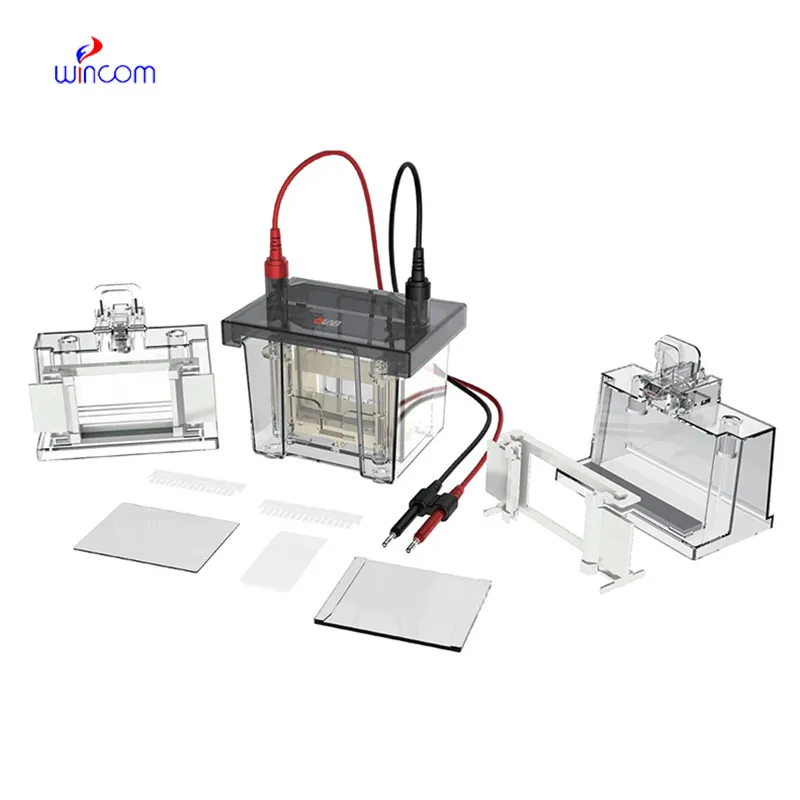

The clinical centrifuge is a staple equipment in laboratories, industries, and research facilities. Its operation is to isolate particles away from one another based on density and weight by utilizing centrifugal force. Whether examining biological fluids, purifying chemicals, or testing materials, the clinical centrifuge provides effective separation and purification. Advances in technology have made it faster accurate and automatic, enabling processes to be more repeatable and consistent. From clinical diagnostics to environmental analysis, clinical centrifuge are essential in furthering precision, productivity, and scientific innovation globally.

Q: What factors affect the performance of a centrifuge? A: Performance depends on rotor design, speed accuracy, load balance, and regular maintenance of mechanical and electrical parts. Q: How should a centrifuge be cleaned? A: Use a soft cloth and mild detergent to clean the chamber and rotor, avoiding abrasive or corrosive substances that could cause damage. Q: Can a centrifuge be used for temperature-sensitive samples? A: Yes, refrigerated models are designed to maintain stable temperatures, protecting samples from heat generated during rotation. Q: What does RPM mean in centrifuge operation? A: RPM stands for revolutions per minute, indicating how fast the rotor spins—higher RPMs generate stronger centrifugal forces. Q: When should the rotor of a centrifuge be replaced? A: Rotors should be replaced when signs of fatigue, corrosion, or cracking appear, or after reaching the manufacturer’s specified lifespan.

I’ve used several microscopes before, but this one stands out for its sturdy design and smooth magnification control.

The hospital bed is well-designed and very practical. Patients find it comfortable, and nurses appreciate how simple it is to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We’re interested in your delivery bed for our maternity department. Please send detailed specifica...

We’re looking for a reliable centrifuge for clinical testing. Can you share the technical specific...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China