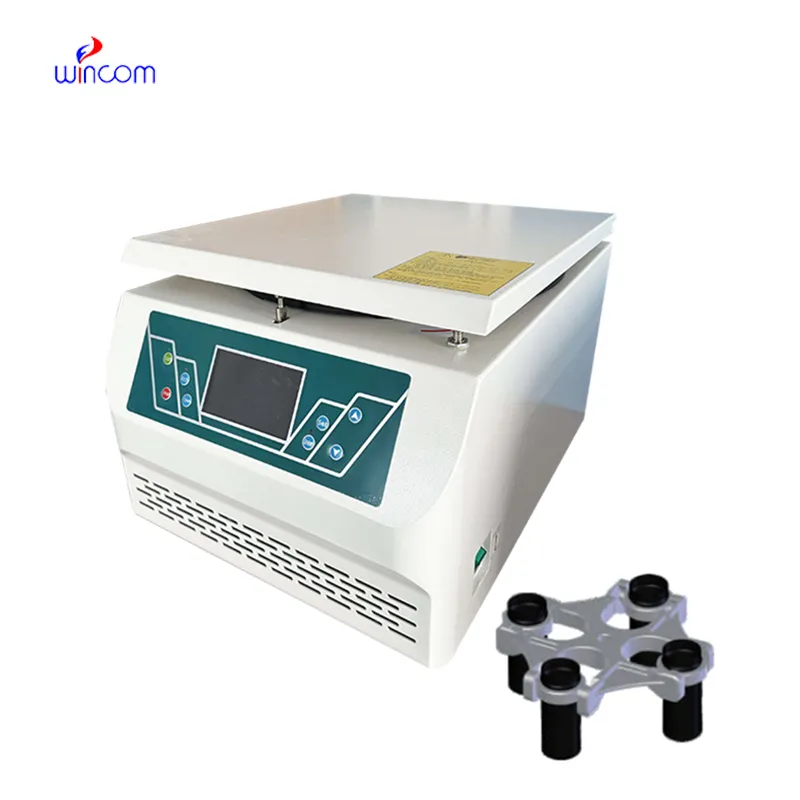

The function of a waste oil centrifuge structure depends entirely on its integrity. Manufacturers now use advanced dynamic balancing techniques to minimize vibration and increase lifespan. High-torque motors give smooth rotational power, and safeguards such as locking lids and imbalance sensors protect the user and sample from injury. In specialized lab arrangements, refrigerated waste oil centrifuge maintain constant temperatures for biological samples. Miniaturized forms are also gaining ground, sacrificing space savings for speed and accuracy. These trends show the ongoing coming of age of waste oil centrifuge engineering into versatility and reliability.

The utilitarian uses of waste oil centrifuge have expanded due to technological advancements. It is utilized in pharmacology to ensure high-purity drug formulations. It is utilized in biotechnology for protein crystallization and vaccine synthesis. The extractive industry utilizes waste oil centrifuge to separate valuable minerals from raw mixture. In classrooms, it facilitates laboratory demonstrations of fluid flow. Even in the restoration of paintings, expert waste oil centrifuge facilitate cleaning and stabilizing delicate pigments. The applicability of waste oil centrifuge to so many different fields is evidence of its utility as an industrial and scientific agent for material separation.

The waste oil centrifuge of the future will be innovative, intelligent, and integrated. With the advent of smart manufacturing, waste oil centrifuge systems will operate independently on predictive analytics. Programs with machine learning will interpret vibration patterns to optimize performance with minimal human involvement. Renewable energy integration will make operation more sustainable, and modular design will facilitate instant replacement of parts. Data visualization software will be more sophisticated, providing real-time feedback on the separation process. This blend of mechanical precision and intelligent technology will place waste oil centrifuge at the forefront of international scientific advancement.

Proper care routines prolong the life of waste oil centrifuge significantly. Operators should inspect the rotor for corrosion or scratches after each use and clean with non-abrasive substances. The lid and chamber should be free from residue to prevent contaminations. Frequent lubrication of mechanical interfaces ensures effortless movement. Temperature and humidity control in the storage room protect internal parts against damage. A maintenance record helps track service time and early wear detection. Ongoing maintenance of these factors allows waste oil centrifuge to perform reliably for decades.

A waste oil centrifuge operates by inducing centrifugal force through rapid rotation, separating substances according to mass and density. It has a critical use in laboratories, medical testing, and industrial treatment. In medicine, for instance, waste oil centrifuge facilitate plasma and serum separation for the purpose of diagnosis. In environmental science, they assist in the examination of suspended solids in water samples. Their robust build, combined with programmable functions and safeguarding features, facilitates fine speed control and timing. waste oil centrifuge continue to evolve to provide faster and more accurate separation procedures in various fields.

Q: What is a centrifuge used for? A: A centrifuge is used to separate mixtures based on density differences by spinning them at high speeds, allowing heavier particles to settle away from lighter ones. Q: How does a centrifuge work? A: A centrifuge operates by generating centrifugal force, pushing denser materials outward while lighter components remain near the center, resulting in effective separation. Q: What are common applications of a centrifuge? A: Centrifuges are used in laboratories, hospitals, and industries for blood testing, chemical analysis, purification, and sample preparation. Q: How often should a centrifuge be calibrated? A: Calibration should be performed at least once a year or whenever performance inconsistencies appear to ensure accuracy and reliability. Q: Can a centrifuge handle biological samples? A: Yes, many centrifuges are designed for biological materials such as blood, plasma, and cell cultures under controlled and sterile conditions.

We’ve been using this mri machine for several months, and the image clarity is excellent. It’s reliable and easy for our team to operate.

This x-ray machine is reliable and easy to operate. Our technicians appreciate how quickly it processes scans, saving valuable time during busy patient hours.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

I’d like to inquire about your x-ray machine models. Could you provide the technical datasheet, wa...

Hello, I’m interested in your water bath for laboratory applications. Can you confirm the temperat...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China