A centrifugal fans is based on a combination of speed, pressure, and design geometry. The development of more advanced rotor designs has optimized airflow and reduced heat generation when operating. Programmable memory is featured in most systems, allowing users to store frequently used parameters to maximize efficiency. Additionally, power-saving motors and sound-dampening enclosures minimize lab discomfort. The ability to spin micro and macro volumes with the same reproducibility gives centrifugal fans equipment an edge both in the research and industrial settings. As technology advances, it remains to be at the forefront of precision and productivity.

The versatility of centrifugal fans can be seen in its application to numerous specialized fields. In marine biology, it helps one analyze plankton and microbial samples. In food science, it helps with the accurate measurement of fat and protein content. The electronics sector employs centrifugal fans for purifying liquid crystals and conductive materials. In environmental protection, centrifugal fans facilitate tracking of pollutants and studies on recycling. They aid in veterinary medicine in blood diagnosis and disease investigation. With these uses, centrifugal fans bring about innovation through offering dependable means for analyzing as well as separating materials.

Advances in automation and material science will shape the future of centrifugal fans. Composite lightweight materials will offer increased speed and reduced mechanical stress. Integrated AI controls will streamline rotor performance and balance in real time. The addition of remote operation and touchless interfaces will increase accessibility in sterile environments. As data-driven laboratories expand, centrifugal fans will be connected to cloud-based systems for predictive diagnostics and performance analytics. All these innovations will create a new generation of smart instruments with the capacity to enable high-throughput, complex applications with precision.

For long-term efficiency, centrifugal fans must be maintained with thorough attention to detail of operation. Every rotor and adapter must be checked for integrity before sample loading. After every cycle, the apparatus needs to be washed with neutral detergents and dried thoroughly. Vibration and mechanical stress are prevented by regular tests of balance. Seals and filters need to be replaced according to service schedules. Dust deposition is prevented by keeping the instrument in a covering when not used. If centrifugal fans apparatus is cared for according to disciplined procedure, equipment will give consistent high-performance performance year in year out.

The centrifugal fans is an essential instrument in science and engineering. It is able to separate material constituents based on their differences in density by rotating them at very high speeds. In biotechnology, it is used to purify cells, DNA, and enzymes. In chemistry, it purifies liquids and removes impurities from them. centrifugal fans also play a crucial role in medical diagnosis when preparing blood samples. Their mechanical precision and regulation of speed ensure safe use. Constantly enhanced design and electronic monitoring system development enhances efficiency, and centrifugal fans are thus inevitable in numerous modern applications.

Q: How is a centrifuge different from a mixer or shaker? A: Unlike mixers or shakers that blend materials, a centrifuge separates components based on density through high-speed rotation. Q: What power requirements does a centrifuge need? A: Most benchtop centrifuges use standard AC power, while industrial units may require higher voltage for greater speed and capacity. Q: Can a centrifuge be used in pharmaceutical production? A: Yes, centrifuge equipment is widely used to purify chemical compounds and biological materials during drug manufacturing processes. Q: How do I prevent vibration during operation? A: Ensure all tubes are evenly loaded, rotors are clean, and the machine is placed on a stable, level surface. Q: What is the lifespan of a centrifuge? A: With regular maintenance and proper usage, a centrifuge can last for many years while maintaining consistent performance.

The hospital bed is well-designed and very practical. Patients find it comfortable, and nurses appreciate how simple it is to operate.

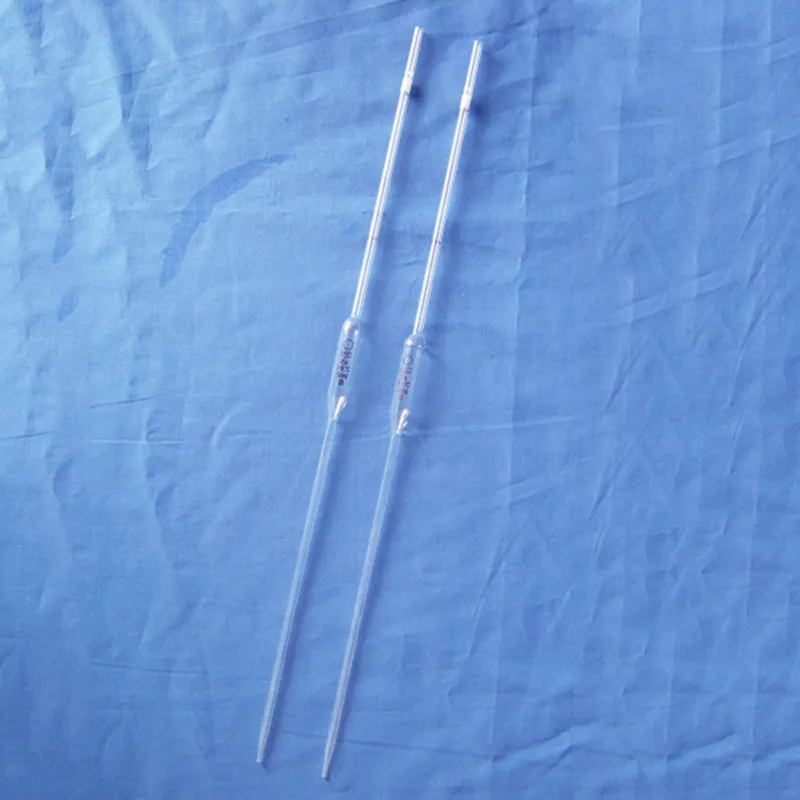

The centrifuge operates quietly and efficiently. It’s compact but surprisingly powerful, making it perfect for daily lab use.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

I’d like to inquire about your x-ray machine models. Could you provide the technical datasheet, wa...

We’re currently sourcing an ultrasound scanner for hospital use. Please send product specification...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China